Flange Mount

Flange Mount Hydraulic Cylinder

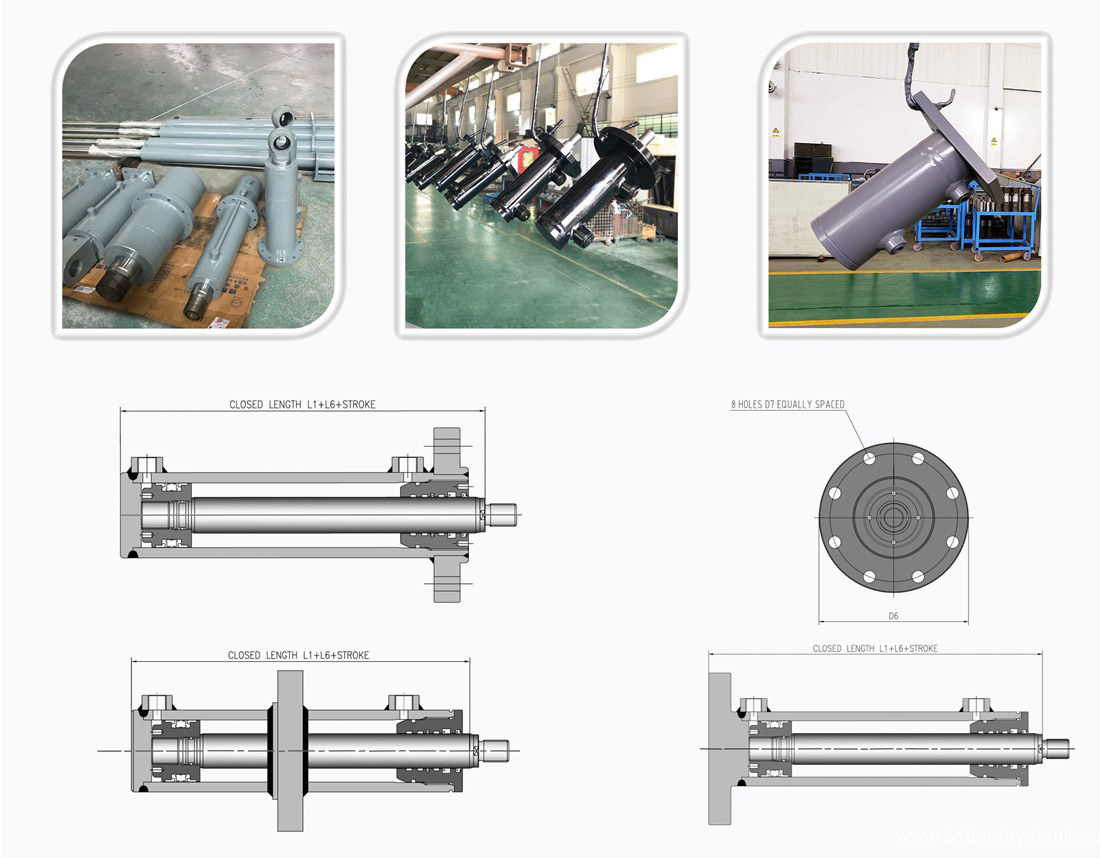

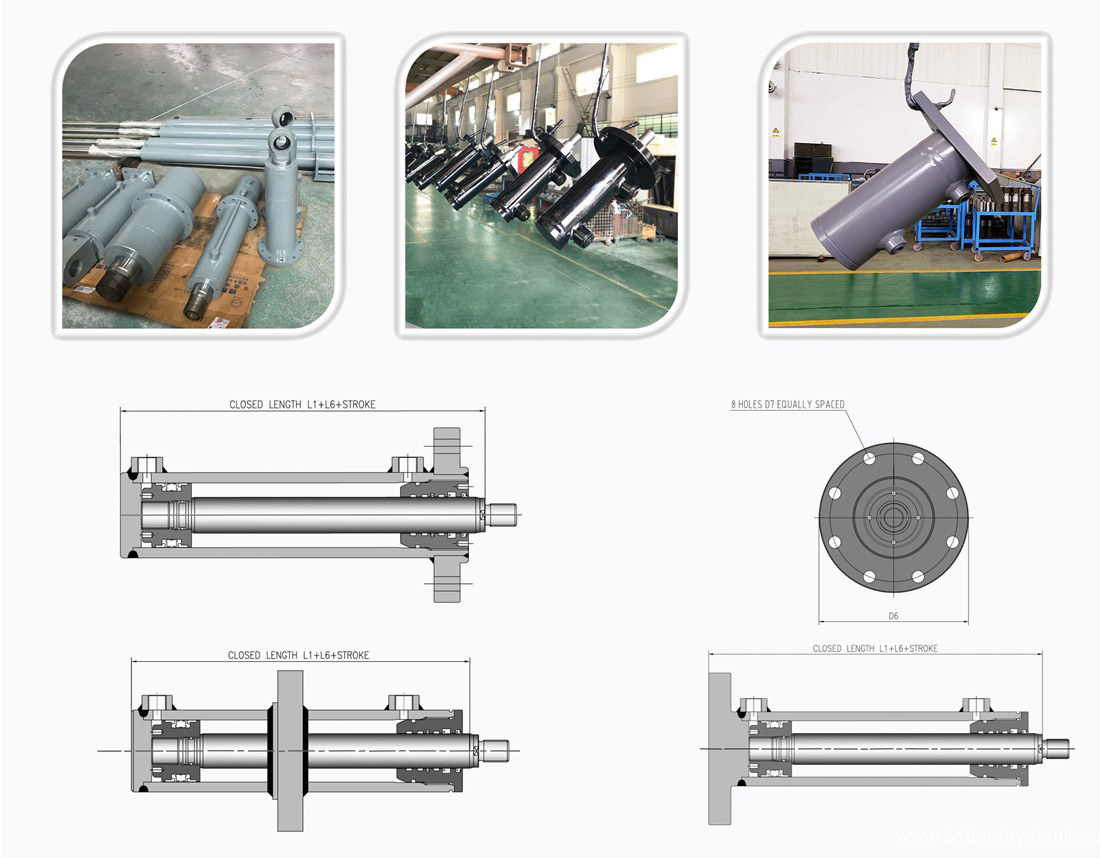

This press cylinders always work in high speed and large shock condition, which is a big challenge for seals and mechanical structure. Thanks to the cooper alloy guide ring, the cylinder can move smoothly and have achieving a high reliability.

flange mount hydraulic cylinders:

-

Flange mount cylinders have mounting flanges with bolt holes integrated at each end to facilitate mounting to machinery.

-

The flanges provide a robust and rigid connection point to attach the cylinder to equipment frames, dies, presses, etc.

-

Common flange styles include SAE square, SAE rectangular, face mount, and tapped holes. The bolt pattern matches up to mating flanges on the equipment.

-

Using a flange mount design helps properly align the cylinder and resist side loads. It also makes installation and replacement easier versus threaded-style mounting.

-

Flange mount barrels are typically made of high strength steel like 4140 or chrome-plated for wear resistance. Flanges are usually steel.

-

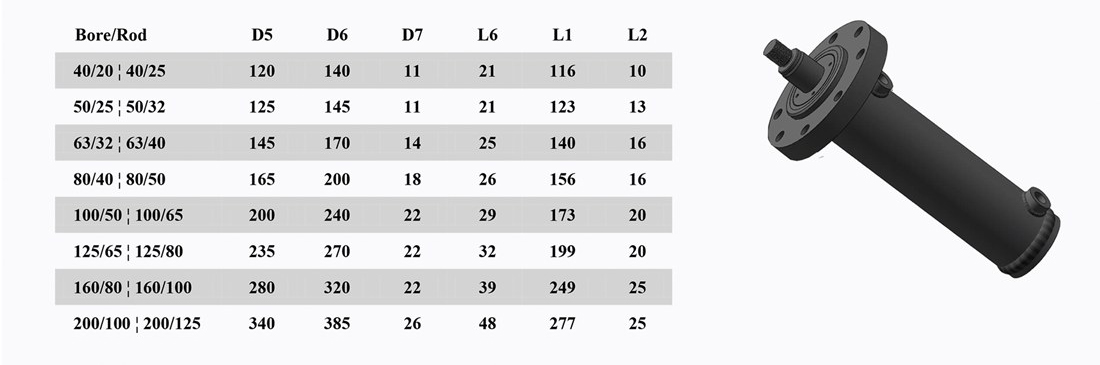

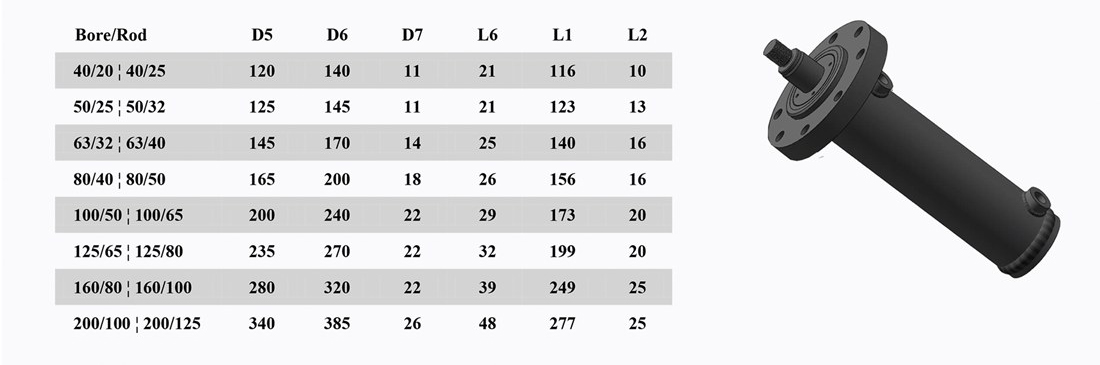

Flange mount cylinders are available in single and double acting designs, with rod diameters from 0.5" to over 10" and strokes up to 120" or more.

-

Industrial applications that use flange mounts include presses, clamps, metal stamping equipment, valves, lifts, and machinery where precise alignment and heavy side loads are expected.

-

Correct bolt torque is important to avoid distorting or cracking the flanges. Lock washers should be used.

-

Overall, flange mounting provides a robust method to install hydraulic cylinders and connect force to equipment while allowing for precise cylinder alignment.

Tag:

Hydraulic Cylinder

Hydraulic Cylinder Single Acting Hydraulic Cylinder

Single Acting Hydraulic Cylinder Standard hydraulic cylinder

Standard hydraulic cylinder Engine Hoist Hydraulic Cylinder

Engine Hoist Hydraulic Cylinder Hydraulic cylinder hoist equipment

Hydraulic cylinder hoist equipment Industrial Hydraulic Cylinders

Industrial Hydraulic Cylinders Carbon Steel Industrial Hydraulic Cylinders

Carbon Steel Industrial Hydraulic Cylinders Cylinder valve servomotor

Cylinder valve servomotor Hard Chromed Rod Surface Treatment

Hard Chromed Rod Surface Treatment cylinder piston rod

cylinder piston rod Cylinder Component

Cylinder Component hydraulic cylinder parts

hydraulic cylinder parts