silinder hidrolik tipe tie rod Presentasi Produk:

Silinder hidrolik tipe tie rod adalah desain khusus silinder hidrolik yang menggunakan batang pengikat untuk menahan tutup ujung ke laras silinder. Silinder ini biasa digunakan dalam berbagai aplikasi industri dan menawarkan beberapa keunggulan. Berikut beberapa informasi tentang silinder hidrolik tipe tie rod:

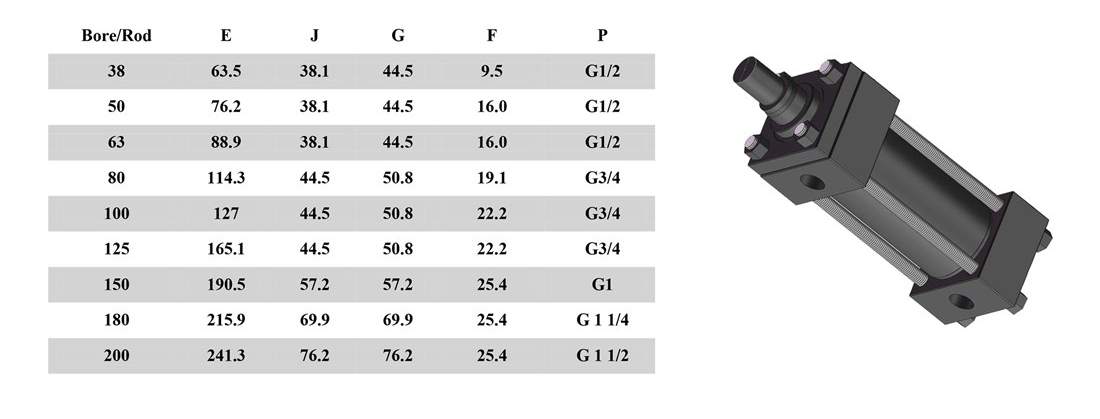

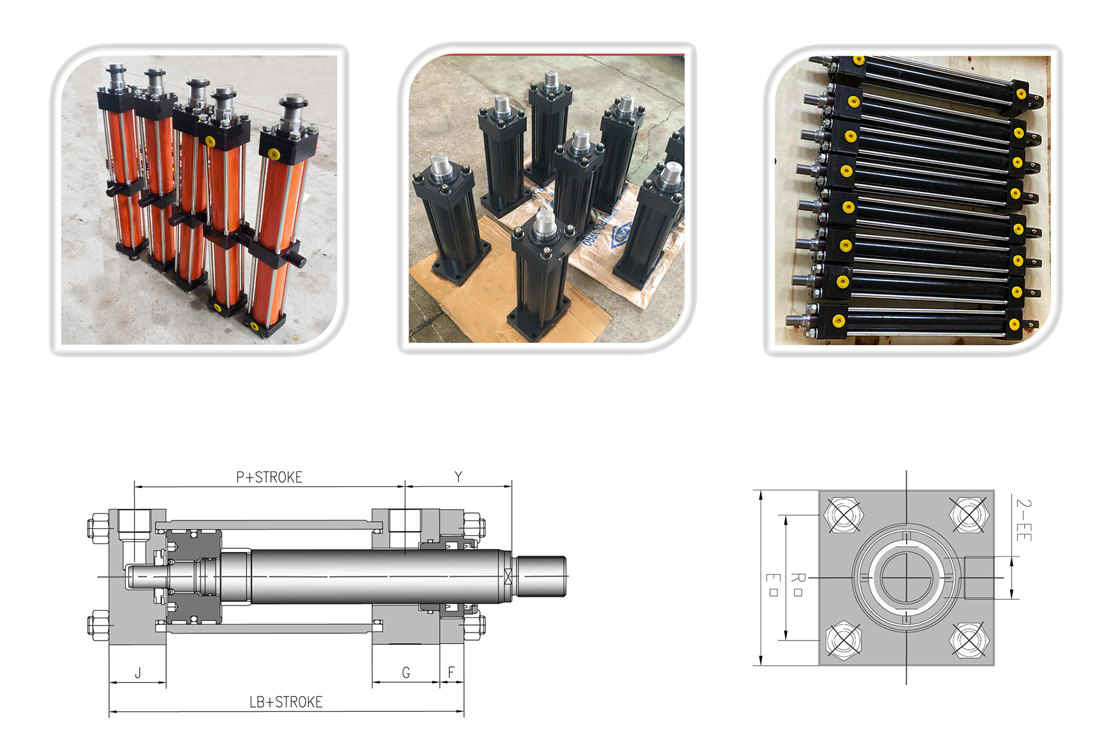

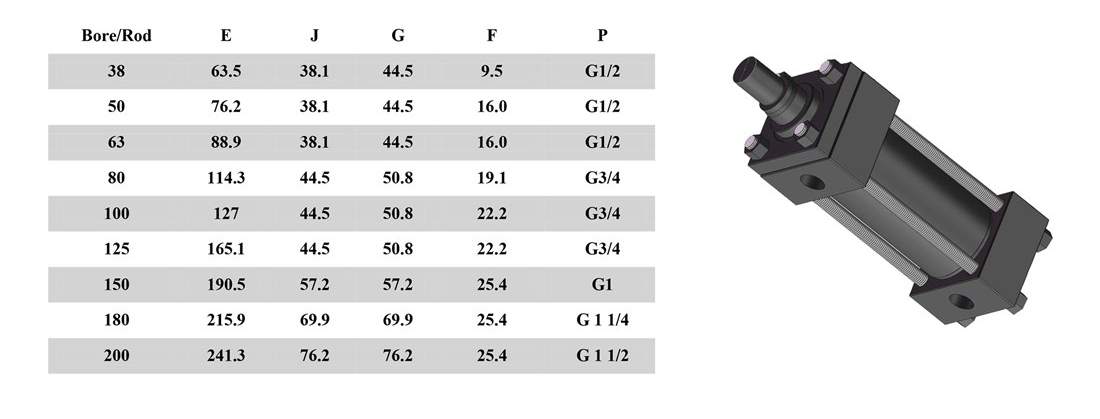

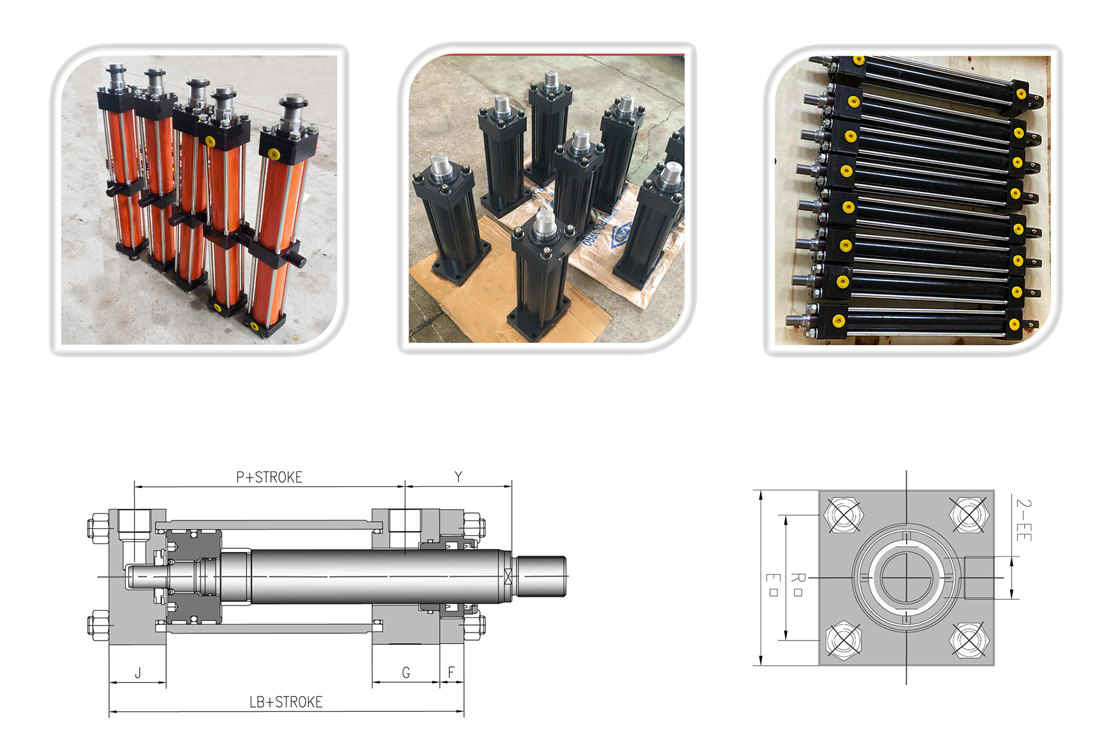

Konstruksi: Silinder tie rod terdiri dari silinder barel, piston, batang piston, penutup ujung, dan batang pengikat. Batang pengikat adalah batang baja berulir yang memanjang melalui silinder&39tutup ujung dan pegang dengan aman di tempatnya. Jumlah tie rod dapat berbeda-beda tergantung pada silindernya&39ukuran dan tekanan operasi.

Manfaat Desain: Silinder tie rod dikenal karena desainnya yang ringkas dan kemudahan perawatannya. Batang pengikat memberikan dukungan struktural, memungkinkan ukuran silinder lebih kecil dibandingkan desain lainnya. Selain itu, tie rod memudahkan pembongkaran dan servis silinder bila diperlukan.

Aplikasi: Silinder hidrolik tipe tie rod banyak digunakan di berbagai industri, termasuk pertanian, konstruksi, limbah dan daur ulang, pembuatan trailer OEM, dan fabrikasi logam. Cocok untuk aplikasi yang memerlukan tekanan pengoperasian sedang hingga tinggi.

Peringkat Tekanan: Silinder tie rod biasanya memiliki tekanan operasi maksimum sekitar

PSI (pound per inci persegi). Peringkat tekanan ini membuatnya cocok untuk berbagai aplikasi industri.3000

Ketersediaan: Silinder hidrolik tipe tie rod tersedia dari berbagai produsen dan pemasok. Beberapa merk ternama yang menawarkan silinder tie rod antara lain Prince, Maverick by Dalton, Cross, dan Dalton Hydraulics.

Saat memilih silinder hidrolik tipe tie rod, pertimbangkan faktor-faktor seperti ukuran lubang, panjang langkah, tekanan pengoperasian, dan persyaratan spesifik aplikasi Anda. Disarankan untuk berkonsultasi dengan pemasok atau produsen terkemuka untuk memastikan Anda memilih silinder yang tepat untuk kebutuhan Anda.

silinder hidrolik tipe tie rod Parameter Utama:

Mereka memiliki badan silinder dengan piston dan batang yang memanjang untuk mentransfer gaya. Tubuh ditutup pada kedua ujungnya dengan penutup ujung. -

Apa yang membuatnya menjadi tipe tie rod adalah bahwa ia memiliki tie rod baja berulir yang melewati bodinya untuk menghubungkan penutup ujungnya. Ini memberikan kekuatan terhadap ketegangan atau gaya penghancur di sepanjang silinder&- poros ; 39

Silinder tie rod dapat menangani tekanan yang lebih tinggi dibandingkan silinder tipe pabrik yang tidak- ;tidak memiliki batang pengikat. Mereka biasa digunakan pada mesin press, klem, pemadat, dan aplikasi gaya tinggi lainnya. 39

Batang pengikat diberi tegangan awal selama perakitan untuk mengurangi tekanan pada silinder. Mereka juga membantu mengurangi distorsi pada badan silinder. -

Mereka biasanya terbuat dari baja untuk kekuatan dan kekakuan. Laras silinder biasanya berupa tabung hidrolik yang mulus. -

Karena adanya tie rod yang melewatinya, maka piston dan rod harus memiliki diameter yang lebih kecil dibandingkan jenis silinder lainnya. Hal ini dapat membatasi kemampuan kekuatan. -

Silinder tie rod memerlukan beberapa perawatan untuk memeriksa torsi tie rod dan menyesuaikan seperlunya untuk mempertahankan pra-tarik. Mur tie rod harus dikunci agar tidak kendor. -

Mereka mungkin memiliki konstruksi yang dilas atau menggunakan konektor berulir. Tipe yang dilas menangani tekanan yang lebih tinggi. -

Secara keseluruhan, silinder tie rod menawarkan desain tugas berat yang cocok untuk aplikasi gaya tinggi pada peralatan manufaktur, pengepres, dan pemadat yang memerlukan kekuatan aksial.

Menandai: