Hard Chrome Plated Honed Tubes represent the pinnacle of performance and durability for hydraulic cylinder barrels. This product combines the dimensional precision of a honed tube with the superior surface properties of a hard chrome plate, resulting in a component engineered for the most demanding industrial applications.

Material Specifications

Base Material:

High-quality, low-carbon or alloy steel seamless tubes are used as the base substrate to ensure structural integrity and strength.

Common steel grades include: ST52. E355. 1045. 4130/4140. or other equivalents as per international standards.

Plating Material:

The interior surface is electroplated with a thick, dense, and uniform layer of Hard Chromium (Chromium, Cr).

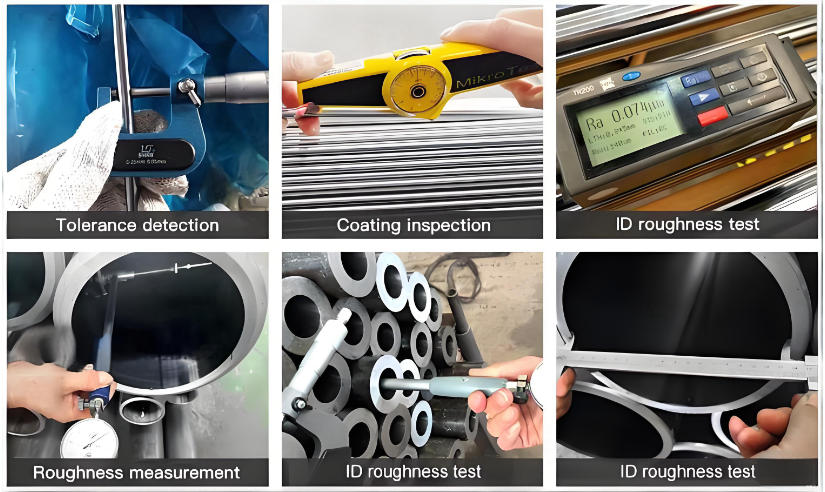

Technical Parameters

| Parameter | Standard Specification | Notes |

| Inner Diameter (ID) | Typically from 30 mm up to 600 mm | Custom sizes available upon request |

| Wall Thickness | Designed to withstand high operating pressures; varies with diameter | |

| Honing Surface Finish | Ra ≤ 0.2 μm (can achieve Ra ≤ 0.1 μm for critical applications) | Mirror-like finish for optimal seal performance |

| Straightness | ≤ 0.5 mm per 1000 mm | Ensures smooth piston travel and prevents uneven wear |

| Chrome Plating Thickness | 30 ~ 60 μm (standard) | Thicker plating (e.g., 80-100+ μm) can be applied for extreme abrasive environments |

| Plating Hardness | 800 ~ 1000 HV (Vickers Hardness) | Significantly harder than the base steel, providing a robust wear surface |

| Chromium Layer Bond Strength | Excellent adhesion with no flaking or peeling | Achieved through rigorous substrate preparation and plating processes |

Tag: 4130 Alloy Steel Honed Tube | Polished Carbon Steel Honed Tubes | Round Carbon Steel Honed Tubes | Hydraulic Cylinder Carbon Steel Honed Tubes | Telescopic Cylinder Honed Tube | Seamless Chrome Plated Honed Tube | Mirror Polished Honed Tube | Thick Wall Carbon Steel Honed Tubes

Inquire Form