BOS Hydraulic's hollow chrome plated rods represent advanced engineering solutions combining structural efficiency with superior surface technology. Manufactured through precisely controlled cold drawing or hot rolling processes and finished with a hard chrome plating (thickness: 5-30μm), these high-precision, lightweight components are specifically engineered for high-strength, wear-resistant applications across hydraulic systems, automation equipment, and engineering machinery.

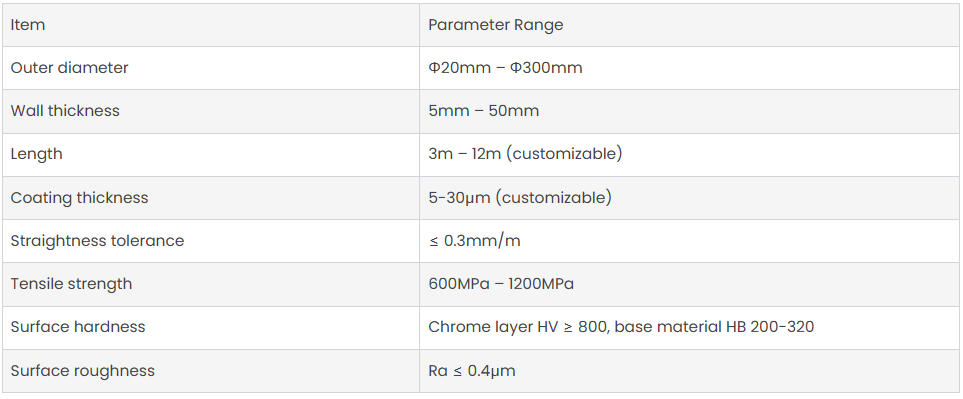

Specifications of Chrome hollow Bar

|

Material grade |

Standard system |

Characteristics |

Applicable |

|

CK45 |

DIN |

Medium carbon steel, quenched and tempered, hardness 28-32HRC, high fatigue resistance |

General mechanical transmission shaft, gearbox support shaft |

|

ST52 |

EN 10025 |

Low alloy high strength steel, yield strength ≥355MPa, good weldability |

Engineering machinery hydraulic cylinder, structural parts |

|

SAE4140 |

ASTM A322 |

Chromium-molybdenum alloy steel, strong hardenability, impact resistance + corrosion resistance |

Heavy-duty gear shaft, oil drilling equipment |

|

SCM440 |

JIS G4105 |

High hardenability, hardness ≥55HRC after high-frequency quenching |

Precision machine tool spindle, automobile steering knuckle |

|

42CrMo4 |

ISO 683-1 |

Ultra-high strength (tensile strength ≥1000MPa), high temperature creep resistance |

Wind power spindle, aerospace components |

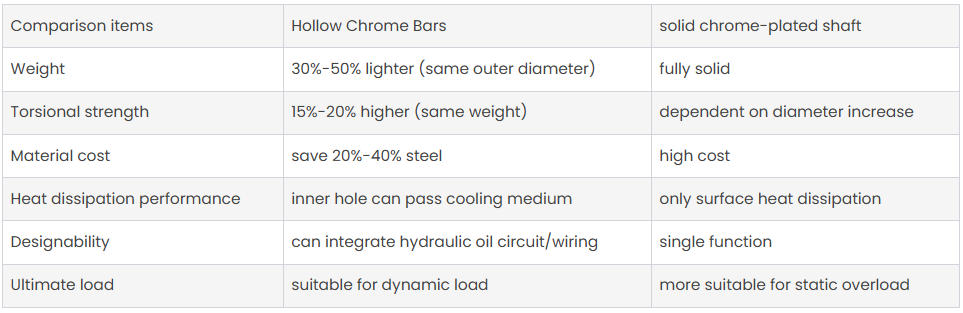

Hollow chrome shaft vs Solid chrome shaft

Technical Parameters

Tag: hard chrome hydraulics | induction hardened chrome rod | 1045 chrome rod | chrome plated steel rod | chrome cylinder rod | hard chrome plated rod | hollow bar manufacturers | brass hollow bar | hollow square bar | st52 hollow bar | cast iron hollow bar | stainless steel hollow rod

Inquire Form