Bos Hydraulic specializes in the manufacture of high-quality OCTG tubing, engineered for oil and gas drilling applications. Our casing products are designed with superior strength and corrosion resistance to ensure long-term well integrity and reliable performance in demanding downhole environments. Available in a comprehensive range of sizes and material grades to suit diverse operational requirements.

Chemical Composition & Mechanical Property

Chemical Composition

| Standard | Grade | Chemical compositions(%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

| Grade | Type | Total elongation under load (%) | Yield strength (min) | Yield strength (max) | Tensile strength min Mpa | Hardness Max (HRC) | Hardness Max(HBW) |

| J55 | – | 0.5 | 379 | 552 | 517 | – | – |

| K55 | – | 0.5 | 379 | 552 | 655 | – | – |

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – |

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | – | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | – | 0.5 | 655 | 758 | 724 | – | – |

| T95 | – | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | – | 0.6 | 758 | 965 | 862 | – | – |

| Q125 | All | 0.65 | 862 | 1034 | 931 | – | – |

Why Partner with Bos Hydraulic?

Direct Manufacturing Advantage: As a factory-direct supplier, we offer exceptional value while maintaining stringent quality control.

Proven Technical Expertise: Years of industry experience enable us to provide solutions that perform under the most challenging conditions.

Rapid Delivery Capability: Our robust inventory management system enables reliable and timely order fulfillment.

Comprehensive Customer Support: Dedicated 24/7 service ensures continuous technical and commercial assistance.

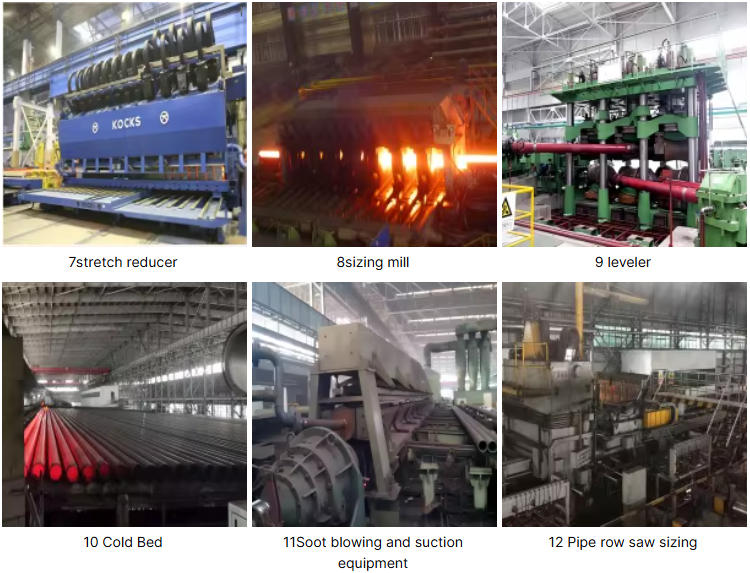

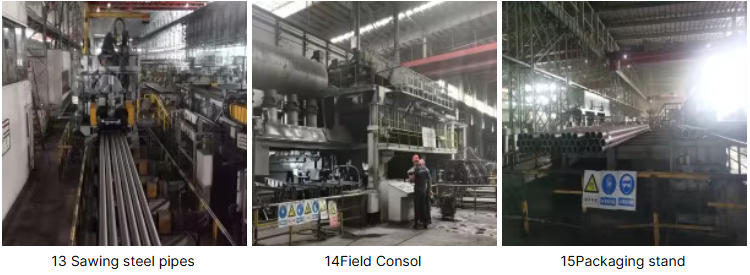

Production process

Tag: seamless steel tubing suppliers | seamless carbon steel | seamless pipe | stainless steel 304 seamless pipe | seamless 304 stainless steel tubing | cs seamless pipe | 3 8 seamless stainless steel tubing | seamless black steel pipe | titanium seamless pipe | cold drawn steel tubing | 304 seamless pipe | galvanized seamless steel pipe | a269 stainless steel tubing | hot rolled seamless pipe | sch 160 stainless steel pipe | hot finished seamless tubing | seamless black pipe | seamless gi pipe

Inquire Form